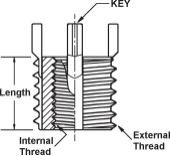

Keensert and Keysert Key locking Inserts provide high strength and reliability and are designed to provide high resistance to rotation and pull-out loads.After installation into the tapped hole, the locking keys on each Keensert are driven down through the threads of the parent material, locking the insert firmly and permanently in place.

Features:

• Easy instll,high strength,high cycle life.

• Positive mechanical lock eliminates wind out in service

• Signicantly increase torque-down and load capability in weaker maerials

• No special taps required

• No tangs to break off and remove

Applications :

• Trucks, RVs

• Machinery, Small Engines

• Molds, Tool and Die

• MRO Tasks

Material: In Carbon Steel - C1215 or equivalent

In Stainless Steel - 303 or equivalent

Keys - 302 CRES or equivalent

Finish: Carbon Steel - Zinc Phosphate

Stainless Steel - Passivated

Tolerances: ±.010 inch or ±.25 mm unless specified otherwise.

Dimensions: Are in inches except metric inserts are in millimeters.

Metric/Inch inserts have a metric internal thread while

all other dimensions are in inches.

Keys: Inserts with an internal thread size of 5/16 or M7 and larger have

4 locking keys,smaller sizes have 2 locking keys.

Tap Drill Hole Tolerance: Inch - .234 to .500 = +.004/-.001

Inch - Over .500 = +.005/-.001

Metric - 6.90 to 10.80 = +.100/-.025

Metric - Over 12.80 = +.130/-.025

TECHNICAL PARAMETER:

Thin wall - Metric Series | |||||||||||

Insert | Installation | Removal | |||||||||

Carbon Part No. | Stainless Part No. | Internal Thread Class 6H | External Thread Class 6g | Length in. | Installation Tool Part No. | Tap Drill Size | C'Sink Diameter +.25/-.00 | Thread Tap | Drill | ||

Size Class 6H | Min Depth | Size | Depth | ||||||||

25847 | 26347 | M2- 0.4 | M4- 0.7 | 3.0 | 24697 | 3.4 | 4.1 | M4- 0.7 | 4.0 | 2.8 | 2.0 |

25848 | 26348 | M2.5- 0.45 | M4.5- 0.75 | 3.8 | 24698 | 3.9 | 4.6 | M4.5- 0.75 | 5.0 | 3.0 | 2.0 |

25849 | 26349 | M3- 0.5 | M5- 0.8 | 4.25 | 24699 | 4.4 | 5.1 | M5- 0.8 | 5.5 | 3.5 | 2.25 |

25950 | 26350 | M4- 0.7 | M6- 0.75 | 5.25 | 24750 | 5.5 | 6.1 | M6- 0.75 | 6.5 | 4.6 | 2.5 |

25951 | 26351 | M 5-0.8 | M8-1.25 | 8.0 | 24751 | 6.9 | 8.25 | M8-1.25 | 9.5 | 5.50 | 4.00 |

25952 | 26352 | M6-1 | M10-1.25 | 10.0 | 24752 | 8.8 | 10.25 | M10-1.25 | 11.5 | 7.50 | 4.75 |

25953 | 26353 | M8-1.25 | M12-1.25 | 12.0 | 24753 | 10.8 | 12.25 | M12-1.25 | 13.5 | 9.50 | 4.75 |

26153 | 26553 | M8-1 | |||||||||

25955 | 26355 | M10-1.5 | M14-1.5 | 14.0 | 24755 | 12.8 | 14.25 | M14-1.5 | 15.5 | 11.50 | 4.75 |

26155 | 26555 | M10-1.25 | |||||||||

25956 | 26356 | M12-1.75 | M16-1.5 | 16.0 | 24756 | 14.75 | 16.25 | M16-1.5 | 17.5 | 13.50 | 4.75 |

26156 | 26556 | M12-1.25 | |||||||||

Heavy Duty - Metric Series | |||||||||||

Insert | Installation | Removal | |||||||||

Carbon Part No. | Stainless Part No. | Internal Thread Class 6H | External Thread Class 6g | Length in. | Installation Tool Part No. | Tap Drill Size | C'Sink Diameter +.25/-.00 | Thread Tap | Drill | ||

Size Class 6H | Min. Depth | Size | Depth | ||||||||

25963 | 26363 | M4-.7 | M8-1.25 | 8.0 | 24763 | 6.90 | 8.25 | M8-1.25 | 9.5 | 5.50 | 4.00 |

25964 | 26364 | M5-.8 | M10-1.25 | 10.0 | 24764 | 8.80 | 10.25 | M10-1.25 | 12.5 | 7.50 | 4.75 |

25965 | 26365 | M6-1 | M12-1.25 | 12.0 | 24765 | 10.80 | 12.25 | M12-1.25 | 14.5 | 9.50 | 4.75 |

25966 | 26366 | M8-1.25 | M14-1.5 | 14.0 | 24766 | 12.80 | 14.25 | M14-1.5 | 16.5 | 11.50 | 4.75 |

26166 | 26566 | M8-1 | |||||||||

25967 | 26367 | M10-1.5 | M16-1.5 | 16.0 | 24767 | 14.75 | 16.25 | M16-1.5 | 18.5 | 13.50 | 4.75 |

26167 | 26567 | M10-1.25 | |||||||||

23596 | 26369 | M12-1.75 | M18-1.5 | 18.0 | 24769 | 16.75 | 18.25 | M18-1.5 | 20.5 | 15.50 | 4.75 |

26169 | 26569 | M12-1.25 | |||||||||

25970 | 26370 | M14-2 | M20-1.5 | 20.0 | 24770 | 18.75 | 20.25 | M20-1.5 | 22.5 | 17.50 | 4.75 |

26170 | 26570 | M14-1.5 | |||||||||

25971 | 26371 | M16-2 | M22-1.5 | 22.0 | 24771 | 20.50 | 22.25 | M22-1.5 | 24.5 | 17.75 | 6.35 |

26171 | 26571 | M16-1.5 | |||||||||

26172 | 26572 | M18-1.5 | M24-1.5 | 24.0 | 24772 | 22.50 | 24.25 | M24-1.5 | 26.5 | 19.75 | 6.35 |

25973 | 26373 | M20-2.5 | M30-2 | 30.0 | 24773 | 28.00 | 30.25 | M30-2 | 34.5 | 25.75 | 6.35 |

26173 | 26573 | M20-1.5 | |||||||||

26174 | 26574 | M22-1.5 | M32-2 | 32.0 | 24774 | 30.00 | 32.25 | M32-2 | 36.5 | 27.75 | 6.35 |

25975 | 26375 | M24-3 | M33-2 | 33.0 | 24775 | 31.00 | 33.25 | M33-2 | 37.5 | 28.75 | 6.35 |

26175 | 26575 | M24-2 | |||||||||

Thin wall - Inch Series | |||||||||||

Insert | Installation | Removal | |||||||||

Carbon Part No. | Stainless Part No. | Internal Thread Class 3B | External Thread (Mod.) Class 2A | Length in. | Installation Tool Part No. | Tap Drill Size | C'Sink Diameter +.010/-.000 | Thread Tap | Drill | ||

Size Class 2B | Min. Depth | Size | Depth | ||||||||

25921 | 26321 | 10-24 | 5/16-18 | 0.31 | 24721 | I | 0.32 | 5/16-18 | 0.37 | 7/32 | 1/8 |

26121 | 26521 | 10-32 | |||||||||

25922 | 26322 | 1/4-20 | 3/8-16 | 0.37 | 24722 | Q | 0.38 | 3/8-16 | 0.43 | 9/32 | 3/16 |

26122 | 26522 | 1/4-28 | |||||||||

25923 | 26323 | 5/16-18 | 7/16-14 | 0.43 | 24723 | X | 0.44 | 7/16-14 | 0.50 | 11/32 | 3/16 |

26123 | 26523 | 5/16-24 | |||||||||

25924 | 26324 | 3/8-16 | 1/2-13 | 0.50 | 24724 | 29/64 | 0.51 | 1/2-13 | 0.56 | 13/32 | 3/16 |

26124 | 26524 | 3/8-24 | |||||||||

25925 | 26325 | 7/16-14 | 9/16-12 | 0.56 | 24725 | 33/64 | 0.57 | 9/16-12 | 0.62 | 15/32 | 3/16 |

26125 | 26525 | 7/16-20 | |||||||||

25926 | 26326 | 1/2-13 | 5/8-11 | 0.62 | 24726 | 37/64 | 0.63 | 5/8-11 | 0.68 | 17/32 | 3/16 |

26126 | 26526 | 1/2-20 | |||||||||

Heavy Duty - Inch Series | |||||||||||

Insert | Installation | Removal | |||||||||

Carbon Part No. | Stainless Part No. | Internal Thread Class 3B | External Thread (Mod.) Class 2A | Length in. | Installation Tool Part No. | Tap Drill Size | C'Sink Diameter +.010/-.000 | Thread Tap | Drill | ||

Size Class 2B | Min. Depth | Size | Depth | ||||||||

25900 | 26300 | 8-32 | 5/16-18 | 0.31 | 24700 | I | 0.32 | 5/16-18 | 0.37 | 7/32 | 1/8 |

25901 | 26301 | 10-24 | 3/8-16 | 0.31 | 24701 | Q | 0.38 | 3/8-16 | 0.37 | 9/32 | 1/8 |

26101 | 26501 | 10-32 | |||||||||

25902 | 26302 | 1/4-20 | 7/16-14 | 0.37 | 24702 | X | 0.44 | 7/16-14 | 0.43 | 11/32 | 3/16 |

26102 | 26502 | 1/4-28 | |||||||||

25903 | 26303 | 5/16-18 | 1/2-13 | 0.43 | 24703 | 29/64 | 0.51 | 1/2-13 | 0.50 | 13/32 | 3/16 |

26103 | 26503 | 5/16-24 | |||||||||

25904 | 26304 | 3/8-16 | 9/16-12 | 0.50 | 24704 | 33/64 | 0.57 | 9/16-12 | 0.56 | 15/32 | 3/16 |

26104 | 26504 | 3/8-24 | |||||||||

25905 | 26305 | 7/16-14 | 5/8-11 | 0.62 | 24705 | 37/64 | 0.63 | 5/8-11 | 0.68 | 17/32 | 3/16 |

26105 | 26505 | 7/16-20 | |||||||||

25906 | 26306 | 1/2-13 | 3/4-16 | 0.62 | 24706 | 45/64 | 0.76 | 3/4-16 | 0.68 | 21/32 | 3/16 |

26106 | 26506 | 1/2-20 | |||||||||

25907 | 26307 | 9/16-12 | 3/4-16 | 0.81 | 24707 | 45/64 | 0.76 | 3/4-16 | 0.94 | 21/32 | 3/16 |

26107 | 26507 | 9/16-18 | |||||||||

25908 | 26308 | 5/8-11 | 7/8-14 | 0.87 | 24708 | 53/64 | 0.88 | 7/8-14 | 1.00 | 25/32 | 5/16 |

26108 | 26508 | 5/8-18 | |||||||||

25909 | 26309 | 3/4-10* | 1 1/8-12 | 1.12 | 24709 | 1 1/16 | 1.14 | 1 1/8-12 | 1.31 | 31/32 | 5/16 |

26109 | 26509 | 3/4-16* | |||||||||

25910 | 26310 | 7/8-9* | 1 1/4-12 | 1.25 | 24710 | 1 3/16 | 1.27 | 1 1/4-12 | 1.44 | 1 3/32 | 5/16 |

26110 | 26510 | 7/8-14* | |||||||||

25911 | 26311 | 1-8* | 1 3/8-12 | 1.37 | 24711 | 1 5/16 | 1.39 | 1 3/8-12 | 1.56 | 1 7/32 | 5/16 |

26111 | 26511 | 1-12* | |||||||||

26112 | - | 1-14* | |||||||||

Company:

Machine Tool Workshop

Imported machine tools and more than 6 devices to detect. Through precision manufacturing processes and strict quality control, we have passed ISO and SGS certifications, also AAA credit in China.

Certification:

We has won more than 200 prizes and 20 patents, we have supplied for Chinese military& aerospace for over 15 years.

FQA

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer since 2004 in Shen zhen ,China .

Q2: Do you have stock for items ?

A2: Yes , most of items are in stock for shippment .

Q3: How long is your delivery time?

A3: Generally it is 1day for stock item,10-15 days for custom items or big quantity over 50000 pcs .

Q4: Can you provide samples ? is it free or extra ?

A4: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q5. What about the payment terms?

A5: Generally 100% T/T in advance before shippment or mass production ,and we can also consult according to your requirement.

Q6: What's your advantage?

A6: The competitive prices, fast delivery and high quality. responsible-oriented employees strict tolerance, smooth finish and long- life performance.

Q7: What are your machining equipment?

A7: CNC milling machines, CNC turning machines, stamping machines,grinding machines,automatic lathe machines, tapping machines, grinding machines,screw machines, cutting machines and so on.

Q8: How to guarantee the Quality of Industrial Parts?

A8: We have been in fastener field over 19 years with full experience. And there are 5 checks in the whole processing, We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts production.

Hot Tags: keensert and keysert key locking insert, suppliers China, manufacturers, factory, buy, in stock, made in China